- December Documentation

- Dec '22 - Jan '23

Related works

Inflatable structures

Inflatable structures are commonly seen in commercial products such as portable rafts and are widely known for their buoyancy and lightweight quality. Various tools have been developed in recent studies to enable users to create intricate shapes for recreational purposes. Recently, inflatables have also been proposed for other practical uses such as inflatable architecture, as soft materials relating to shape-changing interfaces, or as a rapid prototyping method. For example, the Tangible Media Group at MIT created a program called Aeromorph that, inspired by the art of paper folding, utilises rules of geometry to be able to precisely determine the degrees of folding of inflatable structures. BlowFab is a fabrication tool that is proposed as a method of rapid prototyping that combines laser cutting and blow moulding techniques to create 3D inflatable prototypes in a short period of time.

↘ BlowFab ↘ Becky Marshall ↘ Aeromorph ↘ Disney1. Experiments

1.1 2.5D Geometric Objects

1. 3D Pyramids

1.3 Inflatable Pillow

1.4 Embedding a Sensor

1.5 Creating patterns

Extra: Comparing 0.5mm vs 0.25mm sheet thickness

Extra: Glue test

1.6 Shapes

1.6.1 Red blood cell

1.6.2 Starfish

1.6.3 Dumpling

1.7 Random experiments out of curiosity

1.8 Embedding a sensor pt 2

Tools I'm using:

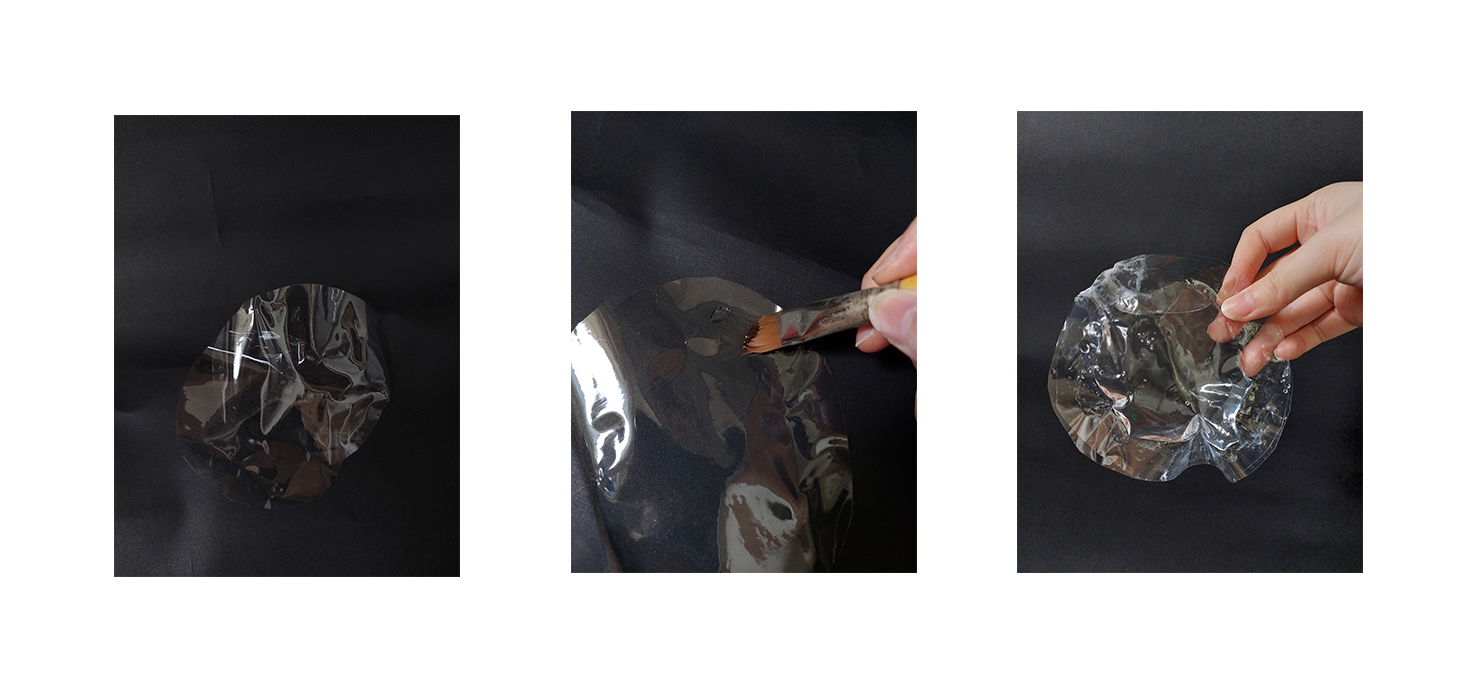

To start my experiments, I'm going to be using glue for crafting. Based on my references, they suggested using PVC cement glue or gorilla glue so I asked around at the shop and this brand of PVC pipe glue was recommended by the shopkeeper. I'm curious to see if different brands of glue would have a different reactions with the plastic so I'll be looking out for more!

Glue test on the plastic

The glue melts the plastic if applied in large quantities, leading to visible deformation on the surface. The area where the glue was applied also becomes more elastic compared to its original state. To test whether the glue is able to form an air-tight bond, I used water to test for visible leakage. It was able to hold the water well! Possible next steps:

(1) Try using a paint brush for more delicate application of the glue (2) Try different shapes (3) Try with inflatable and pump (4) Try different plastic materials (5) Find air valves to test with inflation

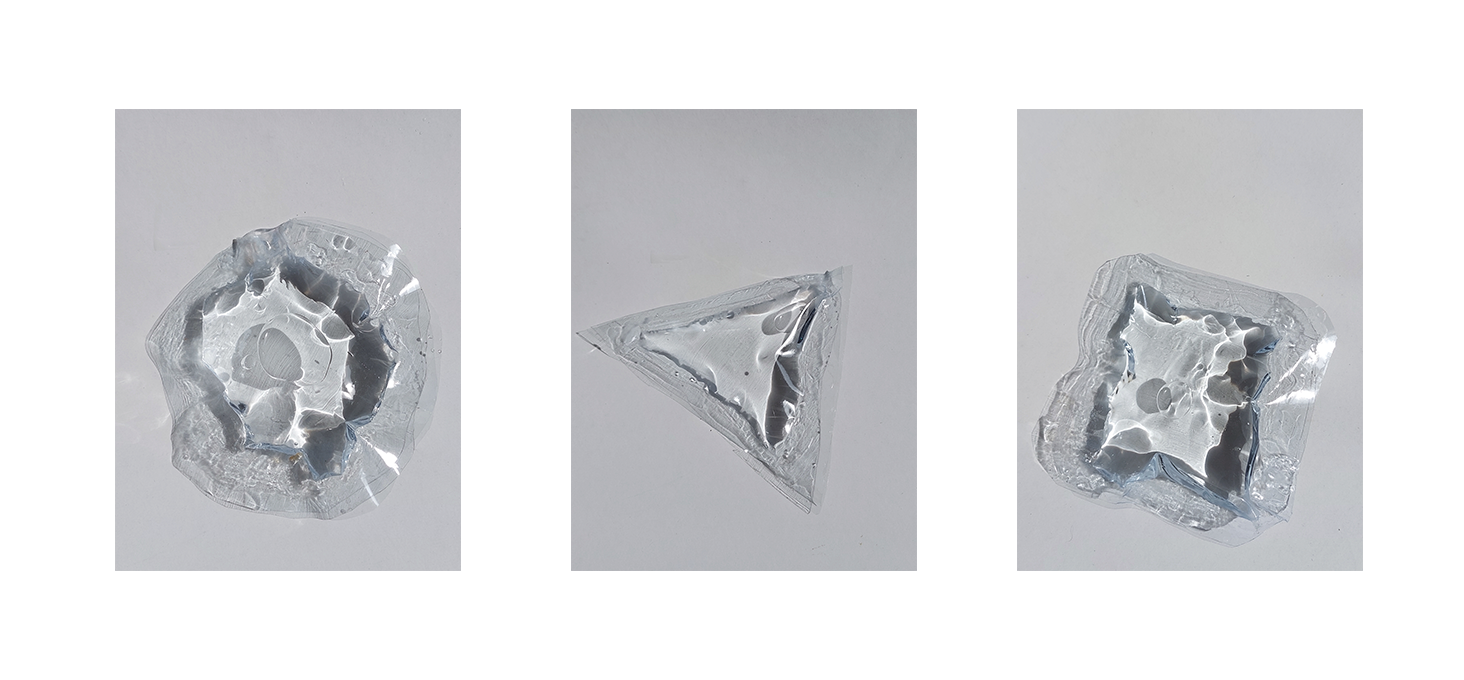

1.1 2.5D Geometric Objects

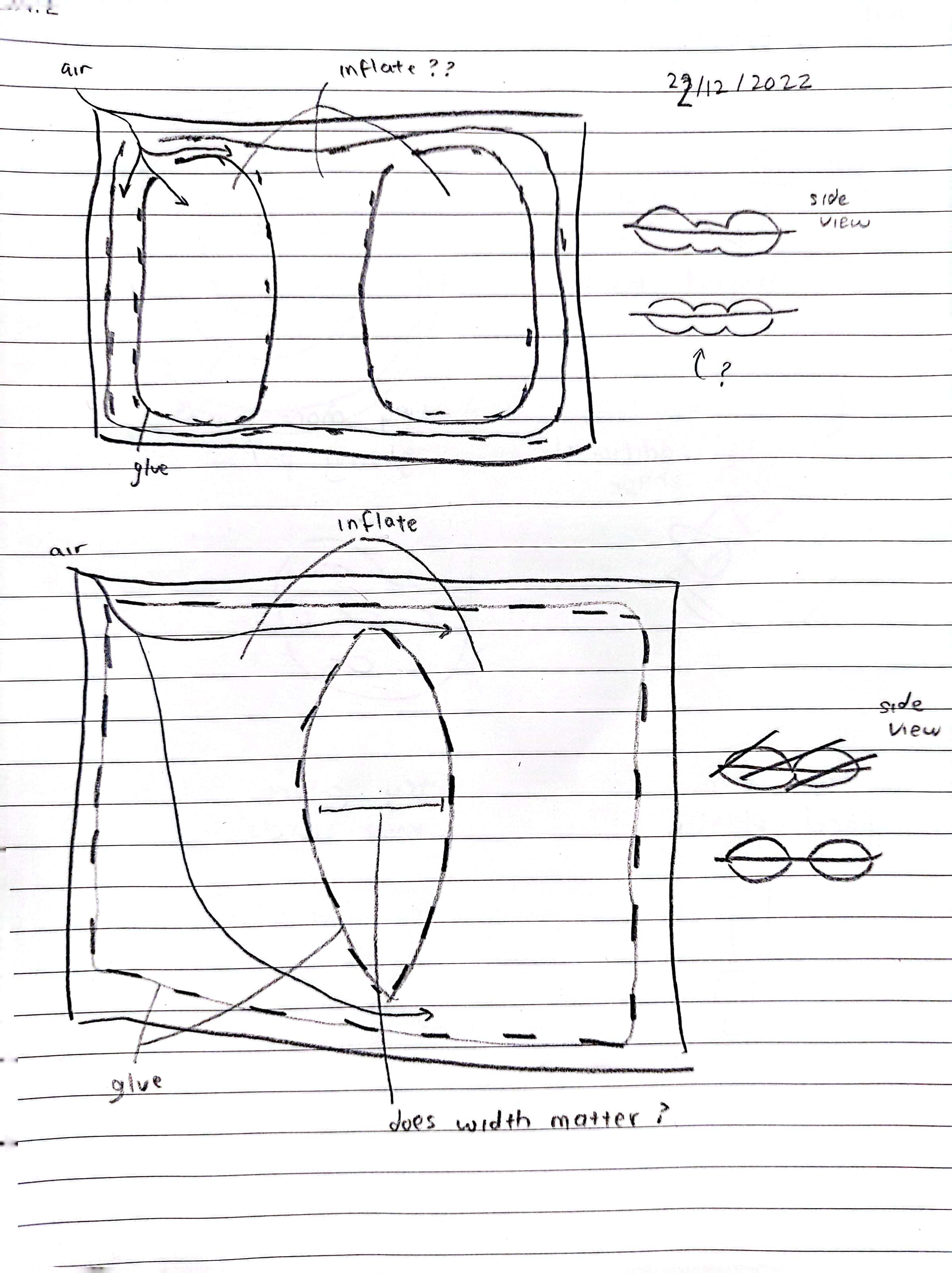

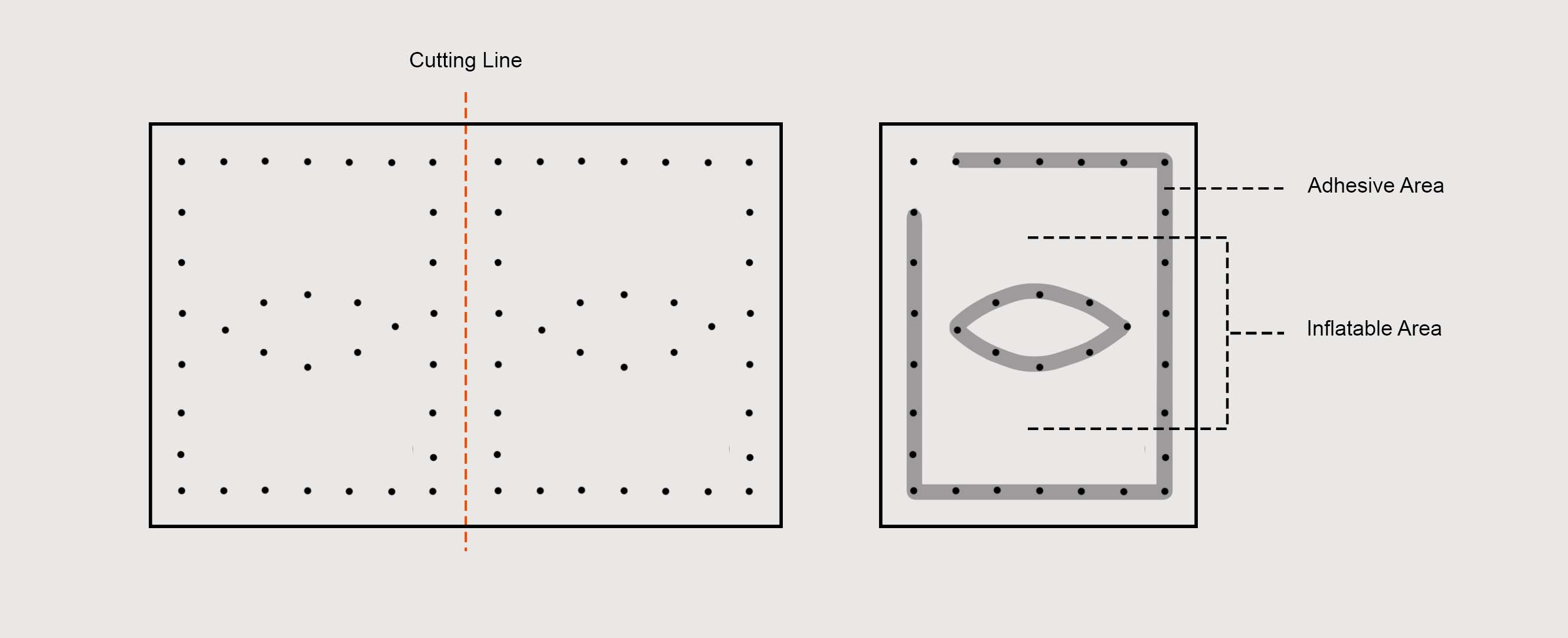

Explorations are conducted through a trial-and-error method as a hands-on learning approach that constructively reflects and builds on previous iterations to achieve the intended results. Starting from geometric shapes, the structure evolves into increasingly complex patterns. First, the sheet is folded once to divide the top and bottom layers of the structure. The cutting pattern was made up of two sections: the adhesive area and the inflatable area. This method not only helps to ensure the cut is accurate but also ensures the alignments of the two layers are accurate as they are bonded together. Next, the sheet is cut around the adhesive area to leave enough space for the glue.

Thoughts & Observations

The shape reminds me of a microorganism. This picture of the larvae of Turritopsis dohrnii or the “immortal jellyfish resembles it the most.

Using a paint brush helps give more control during the application, but paint brush turns stiff super quick so either the paint brush needs to be cleaned immediately after use or look for a more efficient method. Thin layer of glue applied with a paintbrush is enough to form an air-tight bond.

Glue placement and application are very important for the final form of the sculpture. The "pocket" inside the circular one looks very irregular because of the uneven spread of the glue.

Glue test after 48hrs

Tough/stiff. Consistency similar to a plastic bottle. I think the material might be unsuitable to make inflatables because of its stiffness when completely dried. Or maybe the stiffness could be a good thing, for example, to be able to hold the weight of the ultrasonic sensor if it were to be embedded in the structure. Next steps:

(1) Try a more careful application of glue to make the shapes more polished (circle) (2)Try 3D shapes next with water first (3) Source other material for trial (PVC inflatable balloon)

1.2 3D Pyramids

Net A

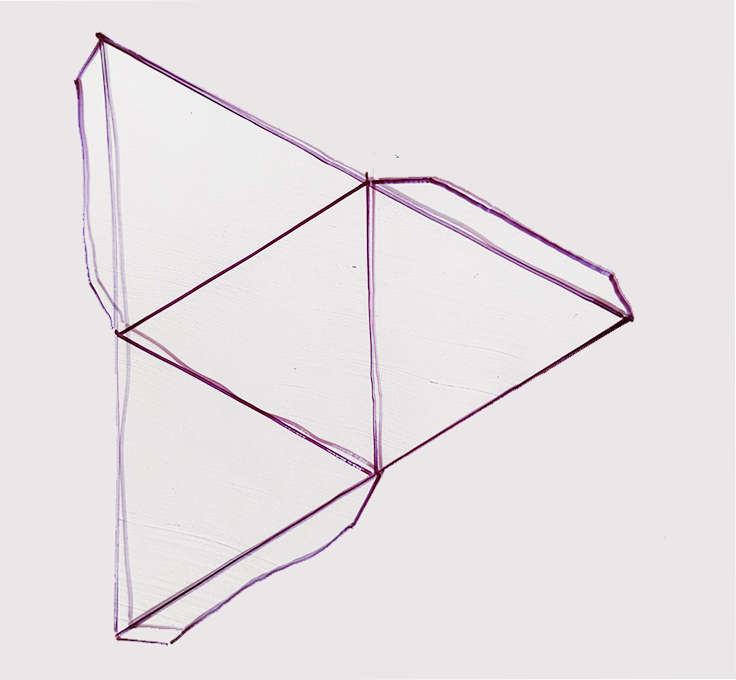

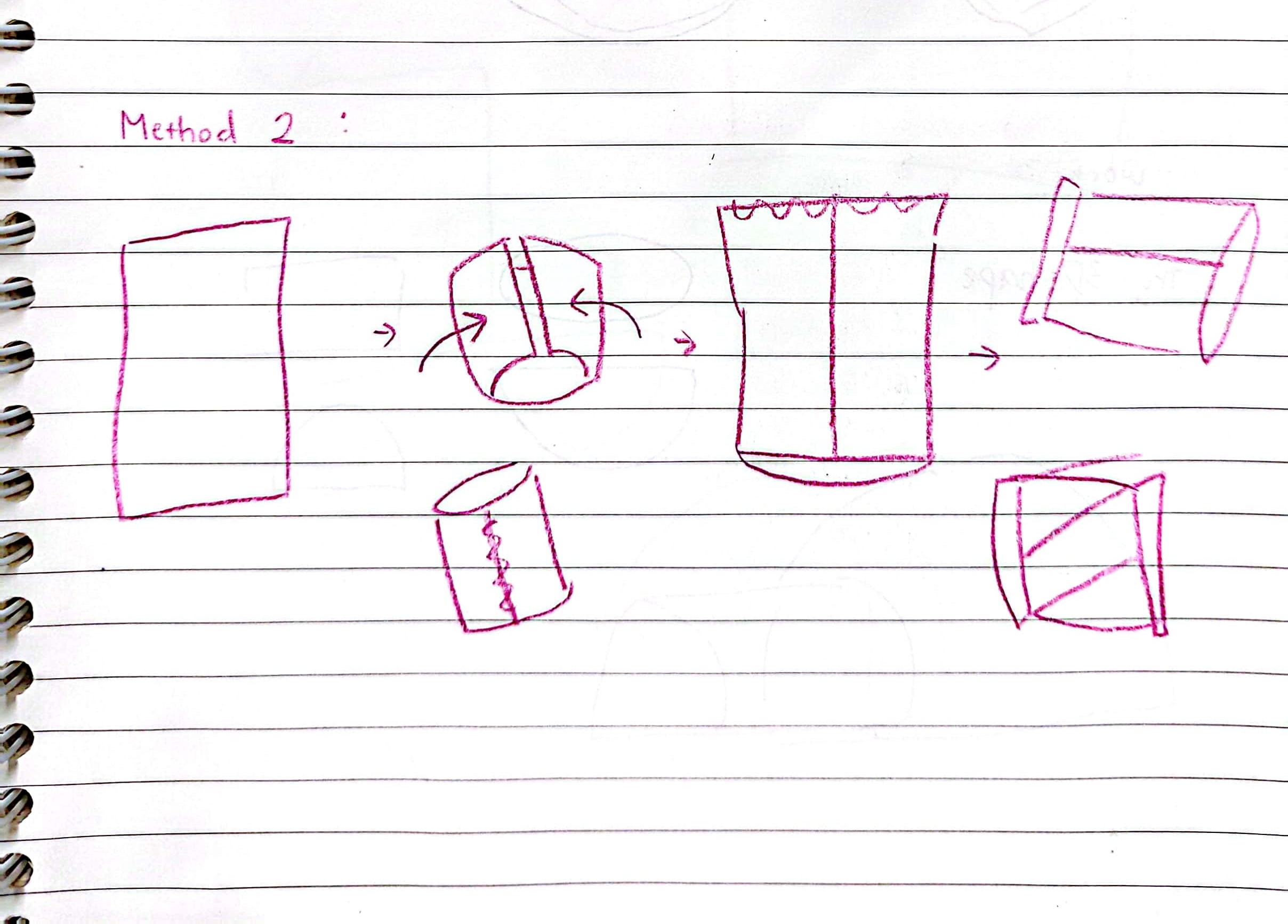

Comparing folding techniques

Moving on from the previous experiment, I moved on from 2.5-dimensional objects to attempting a 3-dimensional object. Triangular pyramids were crafted using two different folding techniques, Net A and Net B, to observe if they affected the chances of leaks forming on the structure.

The corners of the pyramids were sharp and requires high precision and perfect alignment in order to achieve a completely air-tight structure. Leaks formed in the corners quickly after inflation with water. Other than that, the plastic appears to be strong enough to hold its shape and support itself even when filled with water.

Afterwards, I started to wonder if using this net design was the best option to make inflatables because they weren't designed with the intention of keeping air or water inside. I suddenly remembered about a particular japanese snack that I had a long time ago that had a triangular packagings. Since food packagings are always filled with air to protect the food from going bad i thought it would be a good source for inspiration as well as making comparison on the two diferent techniques. Does the folding technique/template of the structure matter?

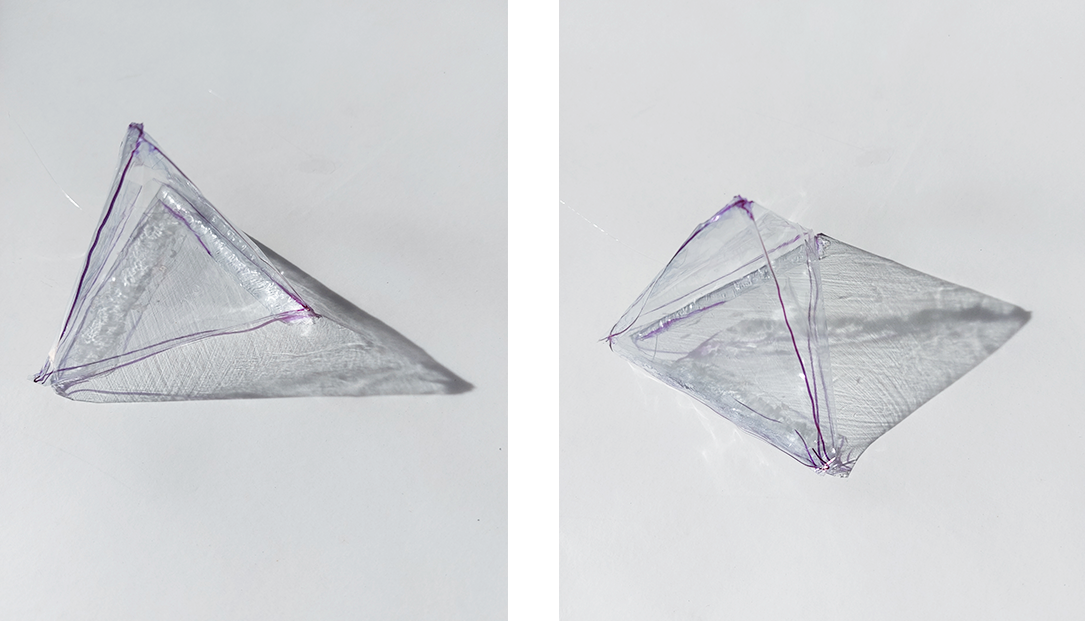

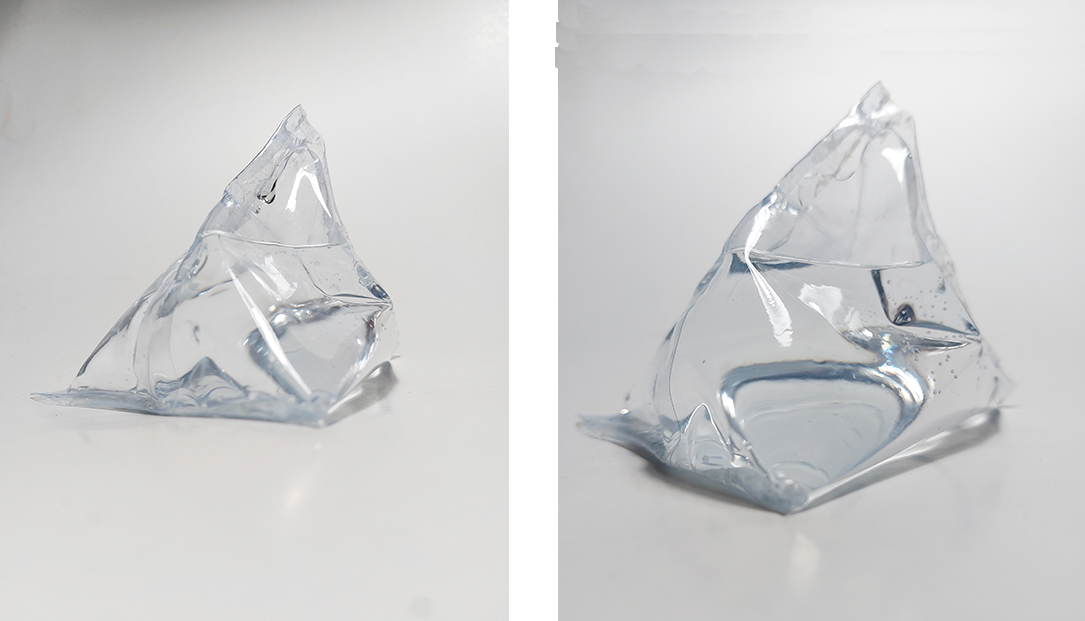

Net B

I found an origami folding technique online to make a triangular packet and followed its directions. It is quite different than the first technique because it puts more emphasis on the folding technique to make the structure, rather than relying on a cutting pattern to get its shape. This teechnique had 1 less adhesive area than Net B which decreased the chances of a leak. Plus the adhesive area was larger in size so there were more surface area for the glue to adhere to.

Net B proved to be more effective than Net A in holding the water inside. The structure was able to hold water in securely.However, the leakproof quality of pyramid B could largely be attributed to its template design which has fewer folds and a larger surface area for the adhesives that cover the corners of the pyramid more securely.

Sourcing New Material

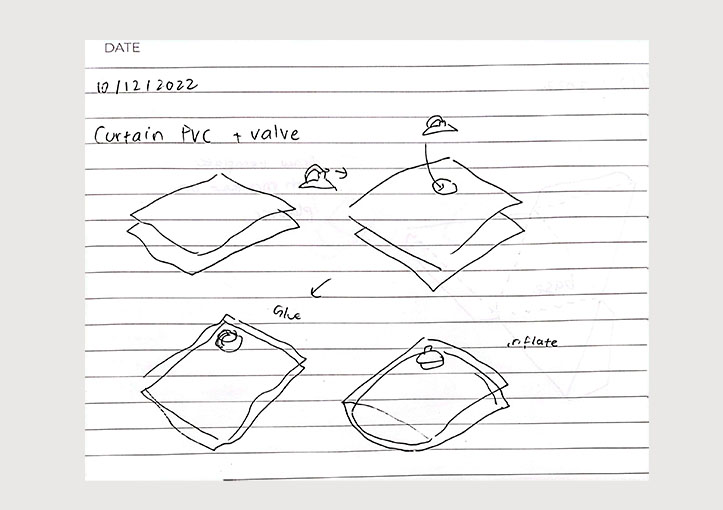

Curtain-type PVC

Towards the end of these set of experiments, I started to get confused because the material wasn't behaving how I expeced to. It lacks in elastic quality I imagined the final artefact to have. With a bit of research, I came to find out that the material I was using had another name, mica or "mika" in Bahasa. “Mika” is made from a type of PVC plastic, though it can also be a mixture of PP, PE, and PVC. But in Indonesia, I discovered that "mika" and "PVC" are often used interchangably even though they have a range of types. I discovered that mika is under the category of rigid-type PVC; usually used for furniture covers to merchandises such as binder covers.

↘ The different types of plastic mica materials.

Google image search for mica in English (Left) shows mostly pictures of the mineral in contrast to searching the Bahasa (Right) which shows mostly the plastic products.

After discvering this, I looked for an alternative type of PVC sheet to test out that had more flexibility and finally found a category of PVC called curtain-type PVC. The curtain-type PVC, as the name suggests, are usually used for curtains in hospitals or carwashes. They come in various thicknesses and, keeping in mind that I wanted it to have some balloon likeness, I picked out 1 metre of the PVC sheet at 0.5mm thickness to experiement on.

1.3 Inflatable Pillow

Moving to air inflation

Since the previous experiments proved that the glue was able to form airtight bonds, I decided to move on from water inflation to air inflation. To do this, I referenced Becky Marshall's steps as a start. In her process, she used an inflatable valve she cut out from a beach ball for her inflatables. I found a pack of unused pool floaties and repurposed the inflation valves from there.

Thoughts & Observations

Hand balloon pump for inflation.

Requires a few rounds of patching-up with glue before the structure is fully air-tight. Leaks usually form in the creases on the sides of the inflatable that might be caused because the top and bottom layers aren't perfectly aligned, or because of the fold marks on the sheet that formed because it was folded during when I got them. Other than that, material definitely more elastic than Mika and more balloon-like.

The inflatable was able to retain its bloated state even after squeezing/dropping it. However I noticed felt some more air leaks located near the area where the valve is stuck in the plastic, possibly because it wasn't secure enough. The inflatable was also unable to retain its fully bloated state because of the time gap between removing the pump and closing valve which lets out a bit of air. The PVC glue reacts to the paint around the inflation valve and strips it. This was an interesting finding considering that I was planning to experiment with colors on the artefact in the future, as suggested by one of the comments during user testing.

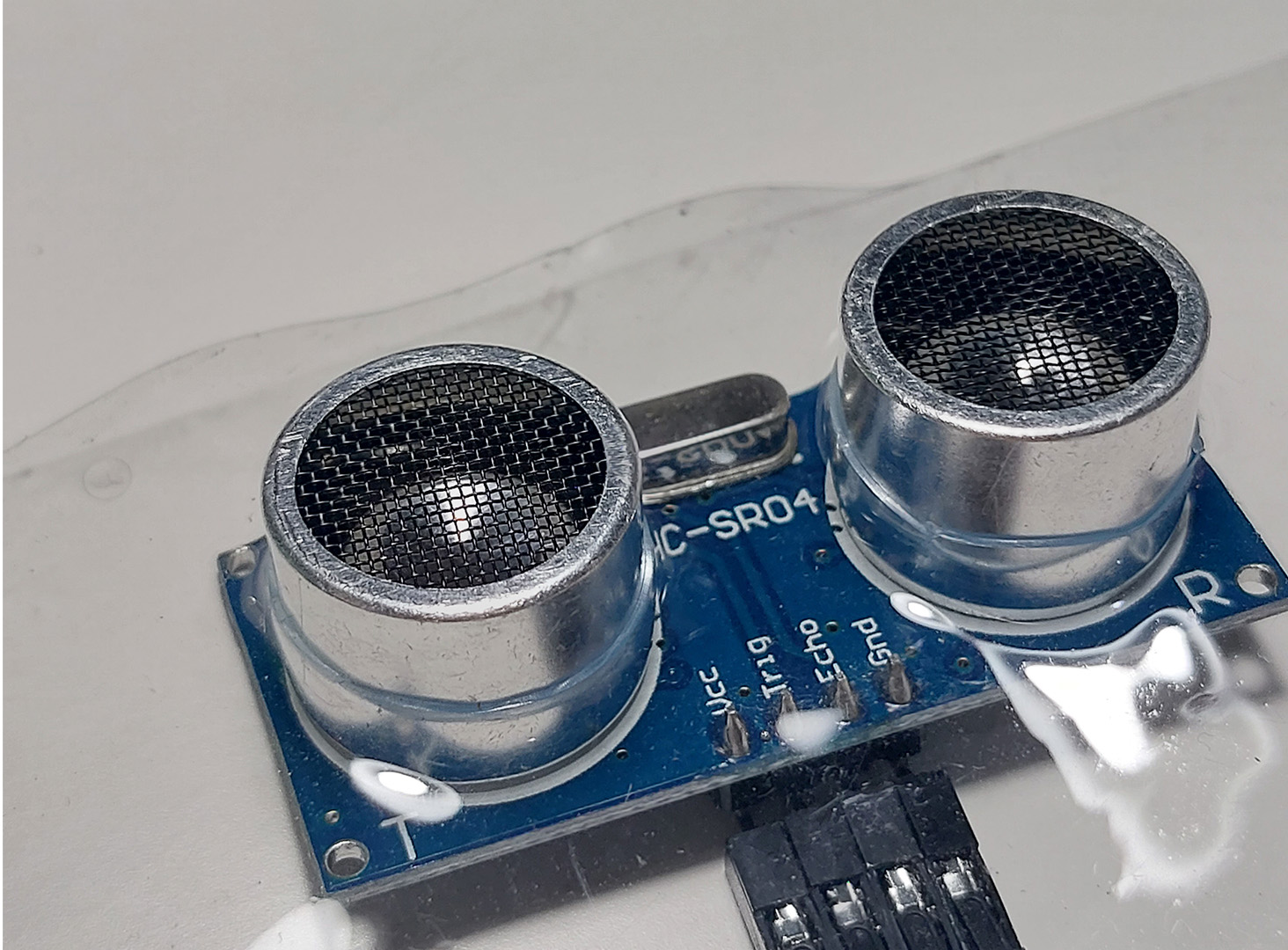

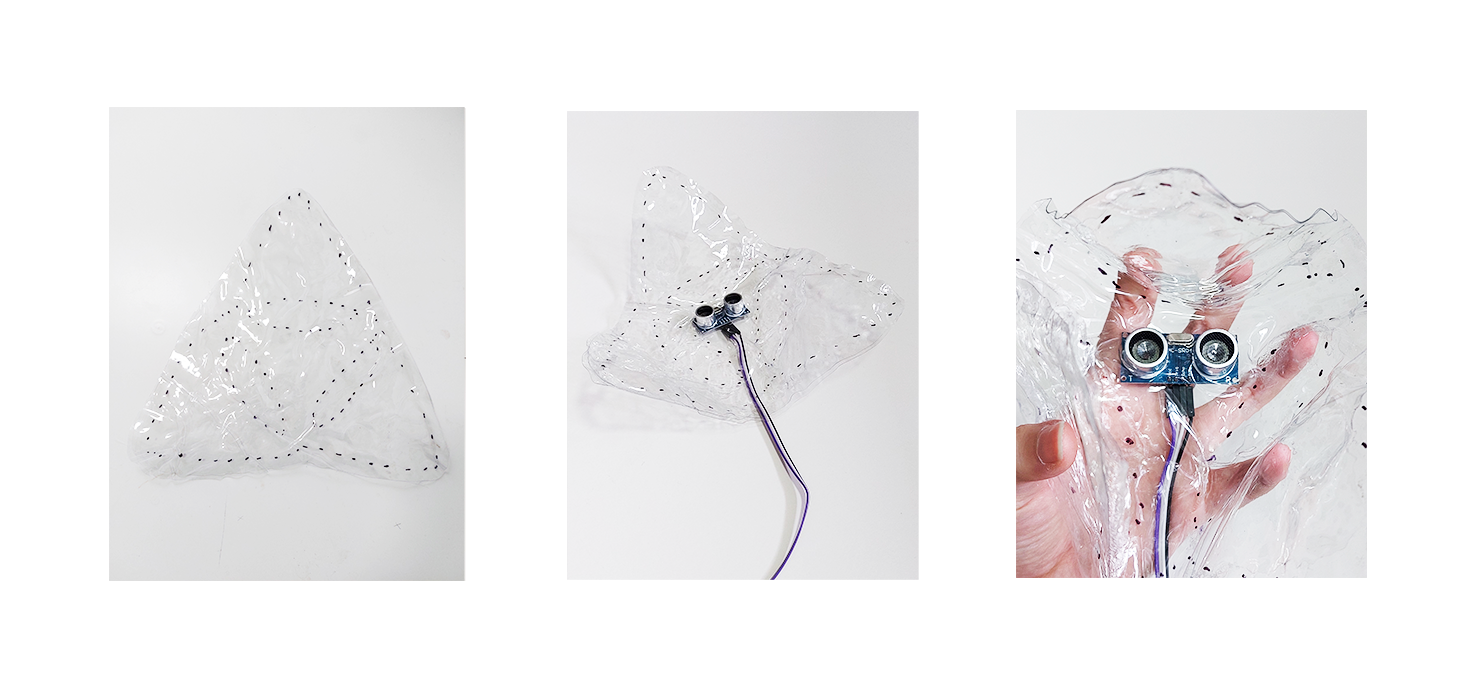

1.4 Embedding a Sensor

This section entails discontinued experiments such as incorporating the ultrasonic sensor and a graphical component on the object. The objective was to observe the plastic’s ability to maintain structural integrity with the sensor in place and still allow for inflation to occur.

Since the nodes on the ultrasonic sensor need to be unobstructed in order for it to work, holes must be cut on the sheet for it to poke through. I cut out a small piece of sheet to test its stretchability. Holes made on the plastic for the sensor are deliberately made smaller to see if it could stretch over the hole and thus hopefully creating an air-tight seal. Results show that the material is stretchable yet still rigid enough to hold the weight of the sensor. Seems like the hole around the sensor is quite airtight. Was going to try and place Arduino inside the cube but not enough space.

Stretch test of the plastic sheet.

Afterwards, I wanted to see how the sensor could be embedded unto the structure. Currently the ultrasonic sensor is connected to the Arduino board through a breadboard which is a bit inconvenient, so instead I used a 30cm male to female jumper wire to connect them directly. For the structure, I decided to start with a geometric shape first. I used a net online to make a 15x15x15 cube.

Thoughts & Observations

For now I think I was able to address one of my worries which is how to create holes for the sensors to peak out from the artifact and have it remain airtight. The weight of the sensor is also no problem, but it also depends on the structure of the artifact itself. The setup later on would be similar to the previous prototype, which is to connect the jumper wires to the Arduino board and it to the laptop.

(1)Explore more inorganic shapes? (2) Think of the wiring situation.What if the Arduino is placed inside the artifact? Where will the sound come from? How does the teensy board work?

1.5 Creating patterns

Moving on from geometric shapes, I wanted to start making a more complex pattern. The shapes are made by sectioning out parts of the plastic to be glued togehter. I used markers to mark the cutting pattern on the plastic so that it is easier to align the top and bottom pieces together. I glued the diamond shape in the centre, as well as the surrounding outer area of the structure while leaving a small section unglued to use as an opening for inserting the air pump.

I ran into an unexpected problem while trying to inflate the structure. At first the air couldn't flow into the other ‘chamber’ , possibly because firstly the air pressure from the pump isn't strong enough to push through the two sheets and because the sheets had a sticky coating and had stuck together, while secondly the air passage was too narrow. I tried using a thin wire to poke around and separate the plastic to hopefully let the air flow inside, but in the end I managed to manually push through the air from one chamber to the next and gradually inflate them.

The air from the pump only flows into the first chamber.

After the structure was fully inflated, I used a clip-on binder as a convenient and quick to seal the opening. I was using an inflatable valve previously but since I had limited quantities, and the purpose of these experimentations were to make various shapes rather than monitor how long the structure stays inflated, I decided to continue using binder clips from here onwards.

Thoughts & Observations

The final structure folds and bends around the diamond-shaped area and was able to prop itself upwards. The structure has a defined curvature and the quality of the material makes it look almost glass-like. Considering the aim to create complex and larger structures for the final series of artefacts, this obstacle of the blocked airflow might create an issue in constructing complicated shapes that involve more sections and separate chambers of air. Possible solutions to avoid the plastic sheets from getting stuck together would be to rub the sheets with alcohol or a mixture of baking soda and water beforehand as its alkaline properties effective at reducing the stickiness on the plastic coating

(1)Leave more room for the air to flow in between chambers (2)Make bigger/longer version (3)Experiment with creating more chambers within one structure to create interesting shapes

Extra: Comparing 0.5mm vs 0.25mm sheet thickness

I decided to experiment with a thinner variant of the PVC plastic sheet to compare the qualities of the final structure in terms of its elasticity and stuctural integrity.

I found that the thinner sheet made the structure more balloon-like and is much more elastic and flexible (left). It was still able to hold its shape as well as the other one but more creases formed on the edges. The elastcity of the thinner sheet also enabled the structure to be more plump.

Video showing the difference in flexibility of the structures made with 0.25mm sheet(left) and 0.5mm sheet (right).

Extra: Glue test

The second trial invovles creating one main chamber that is connected to 6 passages. For this pattern, the air flow will be dispersed; starting from the opening located in the centre chamber and then ideally dispersing at the same rate to the 6 connected chambers.

New glue brand usually used to bond PVC pipes

Hyperlapse of the plastic reacting to the glue

1.6 Shapes

These next series of experiments entails an explorations into creating more chambers and shapes within the plastic structure.

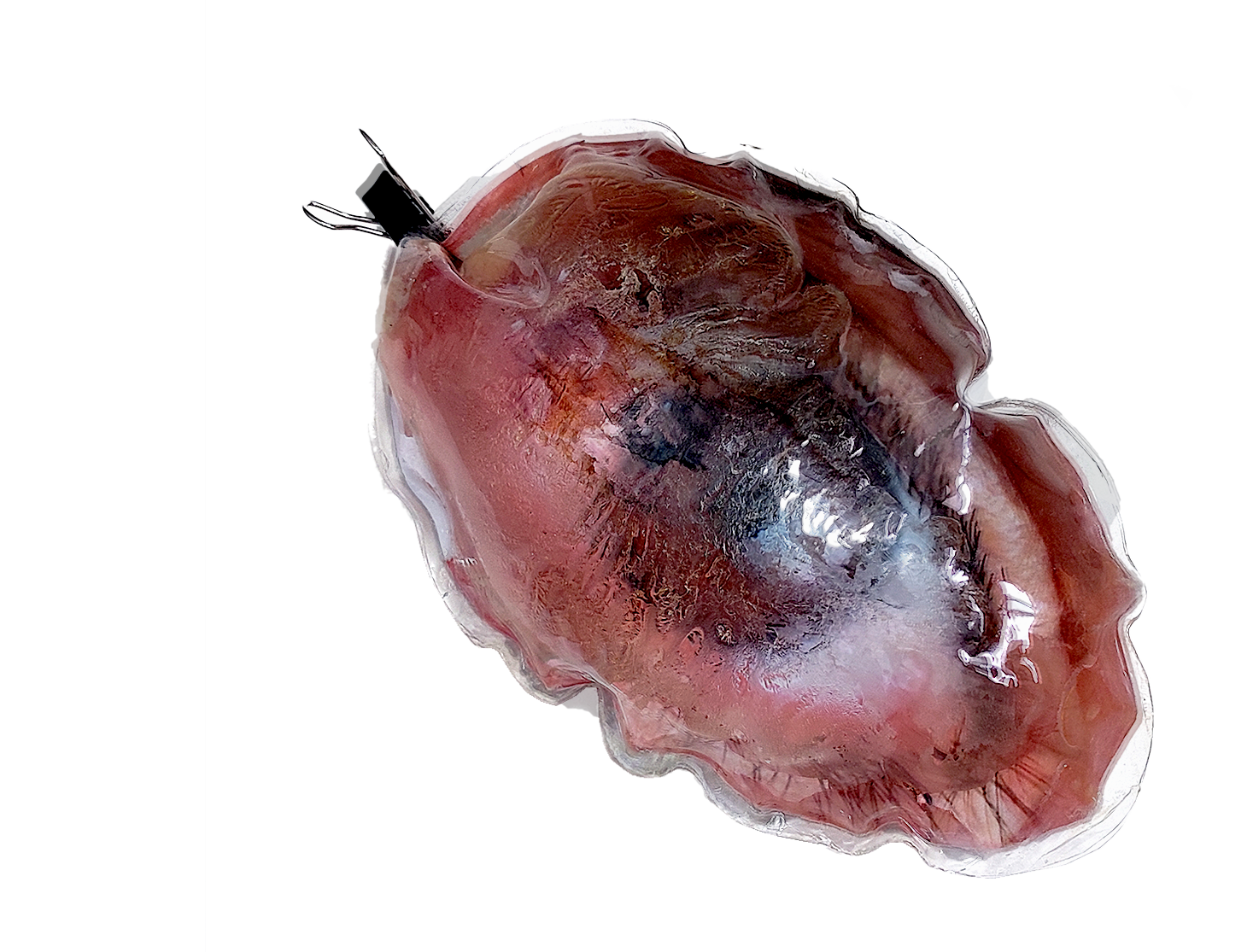

1.6.1 Red blood cell

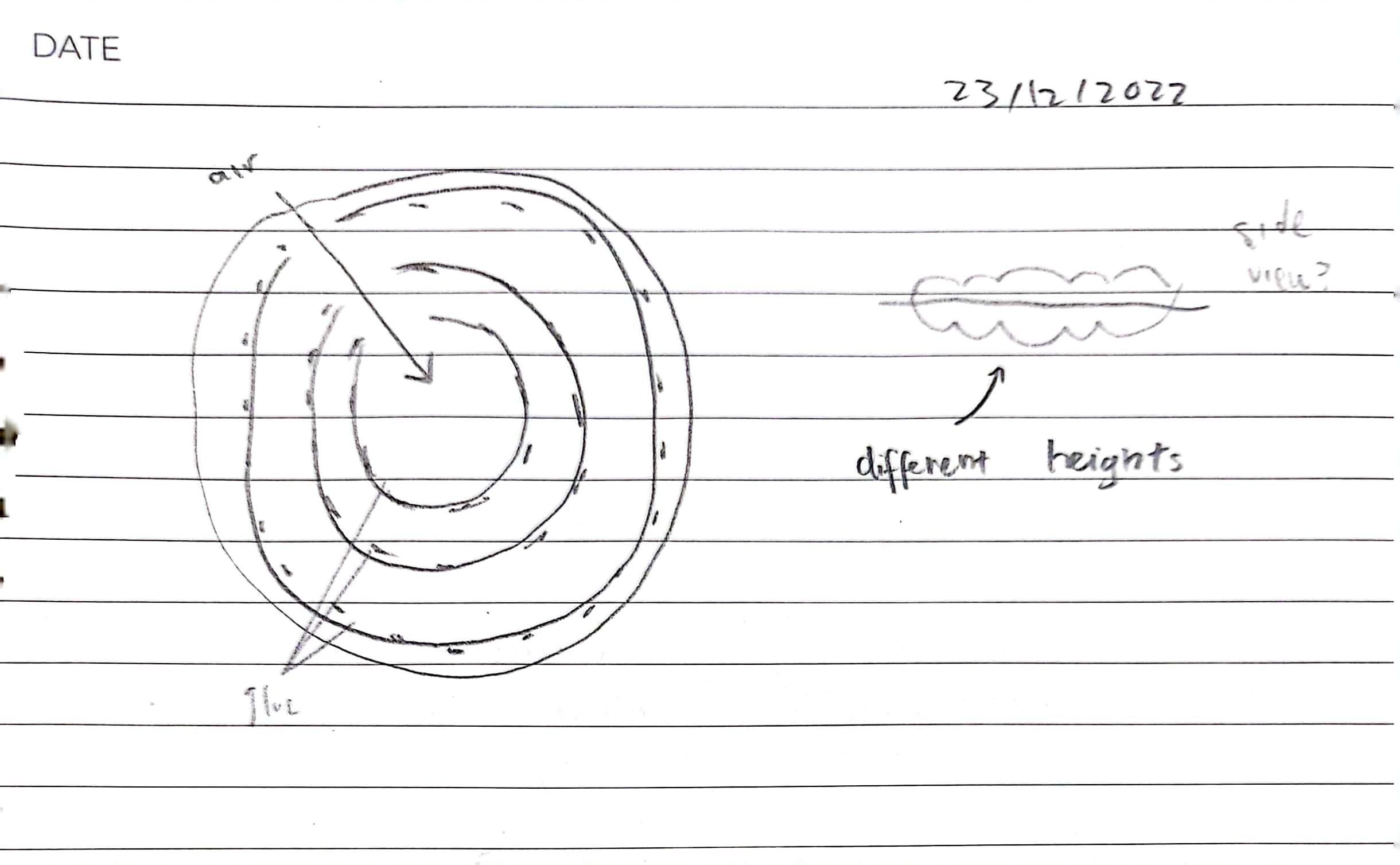

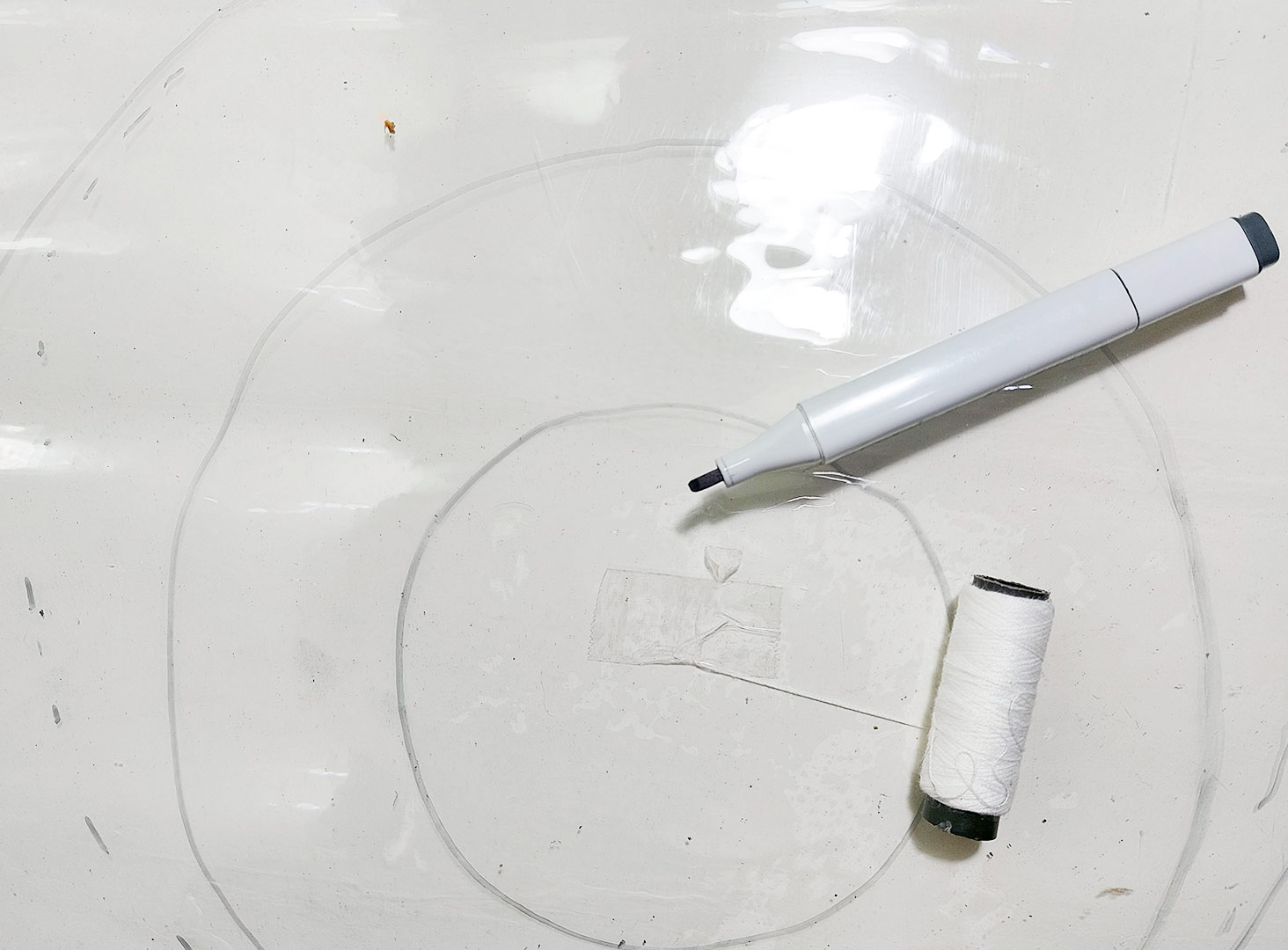

To expand from the previous experiment, I wanted to try making more complicated forms by creating more sections within the object to test the effects of airflow passage in the structure. The first trial involves creating 3 concentric circles that increase in its radius ofeach side by 5cm. The airflow in this pattern will be gradual, starting from the opening in the outer ring and travelling all the way to the centre.

Sketch of the structure.

This probably isn't the best method but I taped a thread to the centre of the circle to aid in drawing out the whole structure.

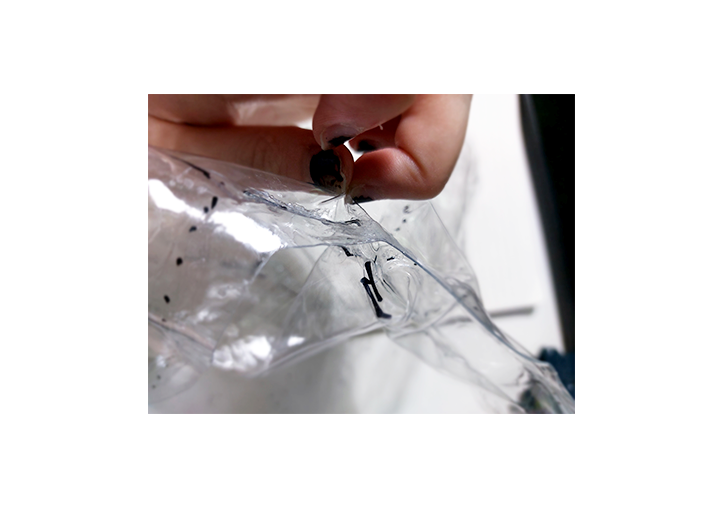

Cutout shape.

Thoughts & Observations

Curves and bends in an unexpected direction. Hypothesized due to the glue placement and effects of the plastic being folded beforehand. Structure holds its shape for a few seconds before deflating, possibly due to an unseen leak that formed due to the creases on the plastic.

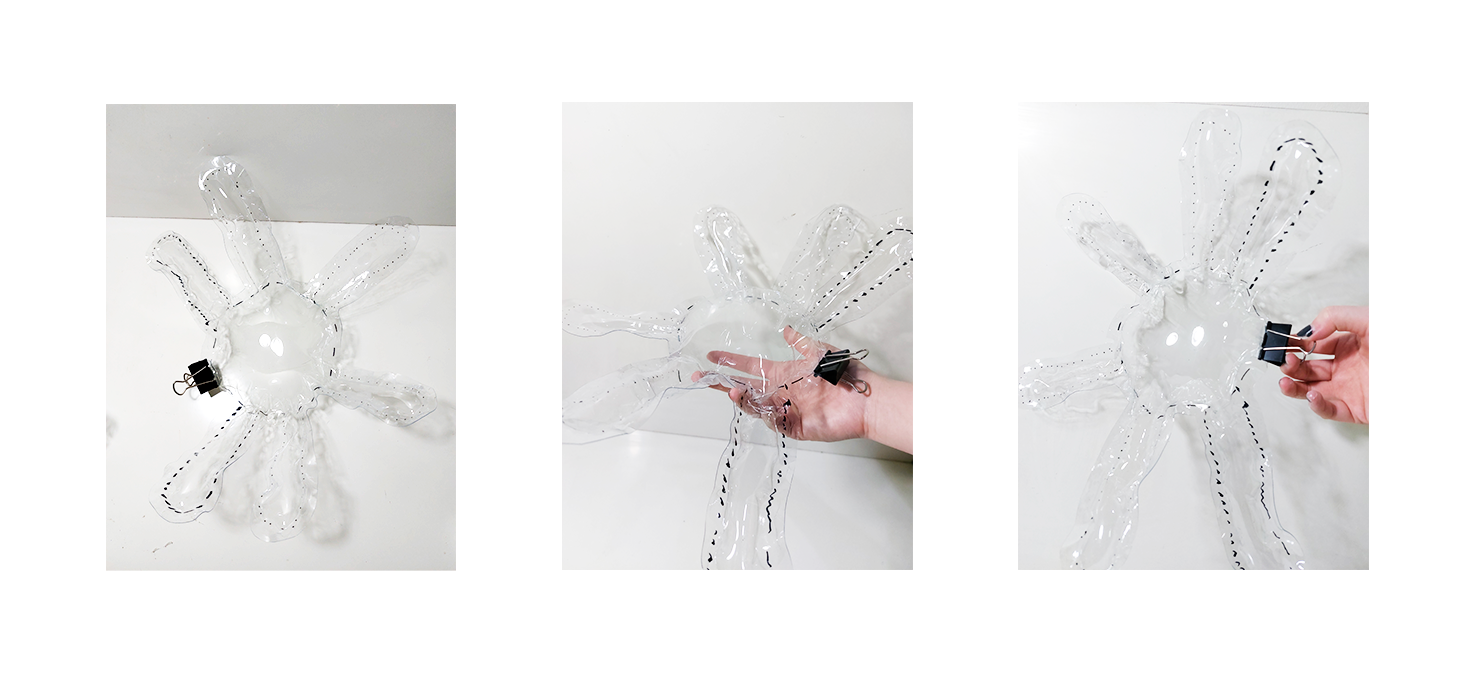

1.6.2 Starfish

The second trial invovles creating one main chamber that is connected to 6 passages. For this pattern, the air flow will be dispersed; starting from the opening located in the centre chamber and then ideally inflating at the same rate to the 6 connected chambers until the structure is fully airated.

Very small leaks tend to form in the corners of the structure.

I faced some difficulties in inflating some of the chambers. The issue was similar with the previous experiment, which is caused by the airway being made too narrow so air couldn't flow inside the chamber. However after a further attempts and trying to manually seperate the plastic sheets so that air could flow in, all chambers were able to be inflated, resulting in a star-like shape.

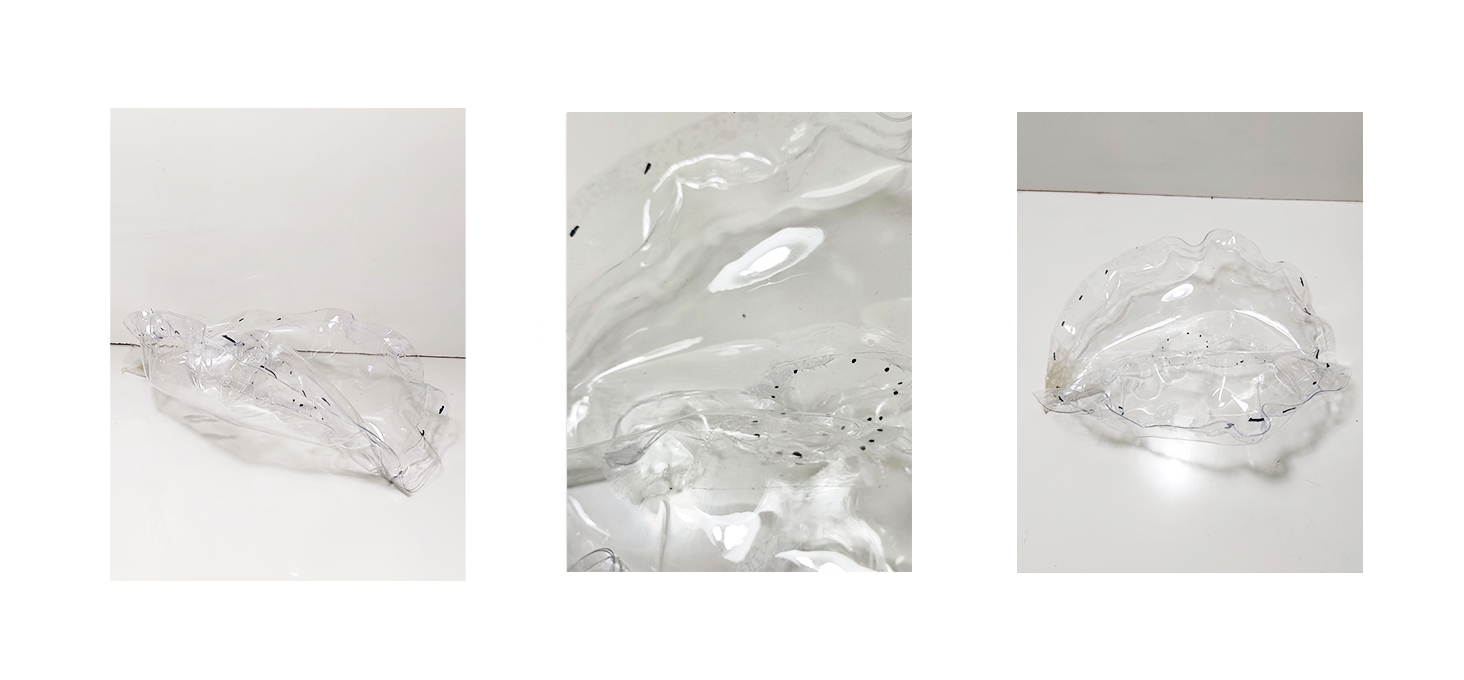

1.6.3 Dumpling

A dumpling shape created by cutting out an elliptical shape, similar to an eye, and gluing the centre to create two seperate chambers.

1.7 Random experiments

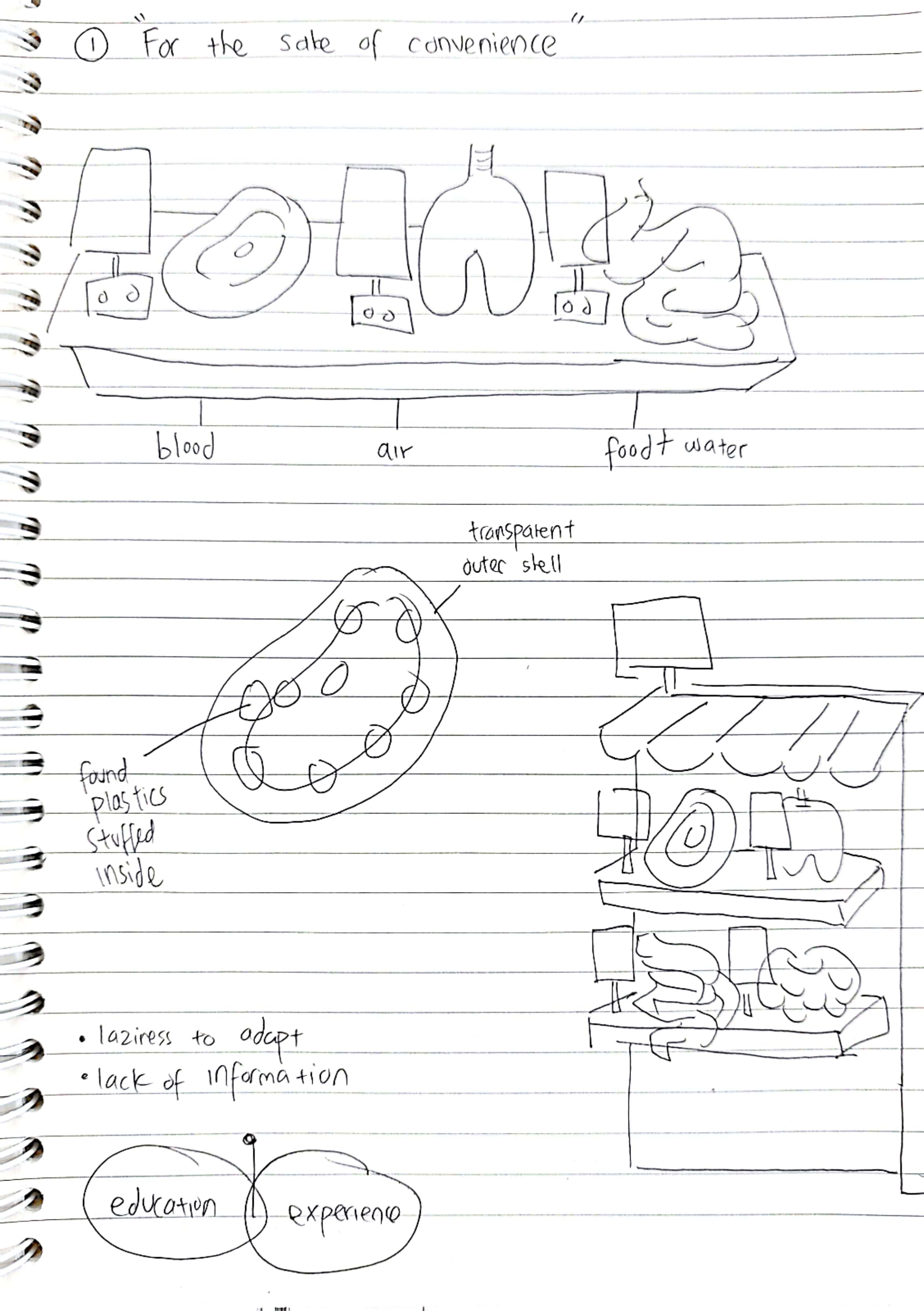

The following experiment was done whilst I was toying with a new idea for the artefacts. I wanted to show the amount of microplastics that have been found inside our bodies as a result of inhalation or consumption. The idea for the artefact is to shape the inflatables into different body parts and fill it up to a number of plastic pieces to correspond to the grams of plastic found inside the body, or use graphics to convey this information.

Sketch of idea called "for the sake of convenience"

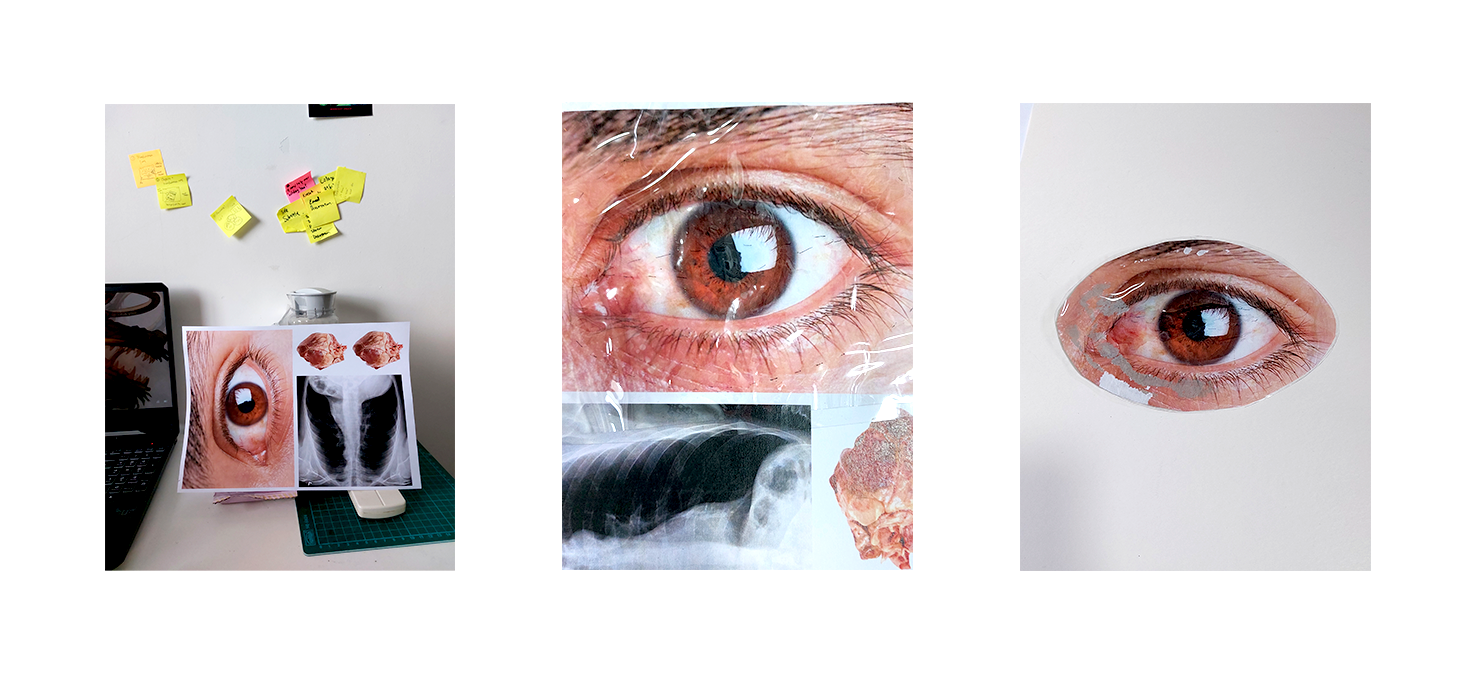

The first experiment involves inserting a printed picture inside the structure that was made in an attempt to explore the possible incorporation of graphics on the artefacts. Two sheets of plastic were cut into a desired shape, and the printed image was sandwiched in between and glued to the bottom layer.

The second experiment involves filling the structure with plastic bits instead of inflating it with air. The plastic bits are compacted inside the plastic to create distinctive patterns and have a rigid feel. The structure is divided into chambers by selctively gluing some parts together.

Thoughts & Observations

I really like how the inflatable looks in combination with the graphics. The inflated object creates an interesting illusion of the 2D image becoming 3D caused by the protrusion of the structure. It was noted that the plastic-based adhesives did not react well with printed ink, hence the discolouration of the plastic. But I think the discolouration actually creates an interesting effect to the visual that kind of shows the ugliness of pollution.

(1) Would be interesting to try and incorporate text (2) Try other body part shapes (3) Try bigger sizes

1.8 Embedding a sensor part 2

This section entails discontinued experiments such as incorporating the ultrasonic sensor and a graphical component on the object. The objective was to observe the plastic’s ability to maintain structural integrity with the sensor in place and still allow for inflation to occur.

Afterwards, I wanted to see how the sensor could be embedded unto the structure. Currently the ultrasonic sensor is connected to the Arduino board through a breadboard which is a bit inconvenient, so instead I used a 30cm male to female jumper wire to connect them directly. For the structure, I decided to start with a geometric shape first. I used a net online to make a 15x15x15 cube.

2. Interview with GIDKP

GIDKP organization logo.

Who is Gerakan Indonesia Diet Kantong Plastic (GIDKP)?

GIDKP is a non-profit organization incorporated as an association that has won numerous honors for its initiatives to make Indonesia free of single-use plastic. GIDKP has been successful in persuading more than 70 cities and government agencies to outlaw the use of single-use plastics by using campaigning, collaboration, and educational strategies.

Among their other achievements, GIDKP was the initiator of the "Non Free Plastic Bag" (#Pay4Plastic) trial in 2016 throughout Indonesia together with the Ministry of Environment and Forestry, which succeeded in reducing plastic bag consumption by up to 55%.

The 2019 Mental Transformation Award from the Government of Indonesia and the 2018 UN Ocean Hero Appreciation are just two of the several honors that GIDKP has received. Also, two documentaries—The Story of Plastic (2019), winner of an Emmy Award, and Plastic Island—covered the work of GIDKP (2021).

Since the organization understands that totally ceasing the use of plastic is a major step, they chose the word "diet" for their name. They promote supporting initiatives to minimize the use of single-use plastic bags by using alternative bags in place of plastic bags.

↘ About the organization. ↘ Published article covering the #Pay4Plastic initiative in 2016.Meet Sarah Rauzana, Senior Education Lead in GIDKP

Sarah is a senior education lead of Indonesian NGO named Gerakan Indonesia Diet Kantong Plastic [ trans: The Indonesian Plastic Bag Diet Movement]. She started working full time in February of 2020, but had previously worked with the organization during her time in college.

What do I hope to achieve from this interview?

So far, all my insights for the issue of plastic pollution in Indonesia were mainly from news outlets, online statistics, and research papers. Hence, in order to grasp the actual events, it was crucial for me to seek out a more realistic point of view of the issue by speaking with someone who have experience dealing with it and are actively involved in promoting change. From the interview, I hope to gain potential insights that I had looked over or unseen patterns that they had noted from their years of experience tackling plastic pollution through educational campaigns and movements, as well as talking about the current obstacles in raising awareness of the issue.

Interview Transcript

[Translated from Bahasa]

1. How long have you been a part of the organization?

2. What compelled you to join this cause?

I started working here full-time since February of 2020, but during college I had exposure to the organization as part of my course in 2018/2019.

At first, I wasn’t fully aware of the issues around plastic waste because I come from a health education background. But what I found most interesting about GIDKP is their very diverse approach towards the issue. Understandably when I first joined, there was a lot of focus on creating campaigns for young children to make them more aware of the issue of plastic waste, but after getting to know the organization more in-depth, I realized that their focus stretched well beyond creating campaigns. They are actively pushing for systematic changes by working together with the Indonesian government. This is why it’s so interesting to me - the organization really tackles the issue from every angle. Secondly, because the organization has such a focus on single-use plastic, it made me realize the severity of the issue.

My initial perception of plastic pollution only revolves around common issues such as littering, but it turns out that after learning together with the organization, the situation is much scarier because plastic material becomes a problem not only after they become trash but starts as early as its production phase. It’s the complexity around the issue that made me interested to delve deeper, and because in my opinion, the issue around the plastic waste is quite underestimated by the public even though we face its effects every day. The problem in my opinion all goes down to trying to break the cycle of our plastic consumption routine. Plastics are a habit, and people are spoiled by their simplicity, their single-use nature, and their cheapness.

Changing our own habits is hard, let alone trying to get other people to change theirs.

Adaptations are often seen as an inconvenience. The issue is getting worse especially now with the rise of online shopping where even small products are coated in layers and layers of plastic.

So that’s why the question is, how do we convince people to change their habits?

3. What is the current state of plastic pollution in Indonesia? Can you explain the dangers of plastic to us?

So in Indonesia itself, it is no longer a secret that the situation is still fairly dire. If you read the news, you'll learn that Indonesia has been listed as the second-largest producer of marine plastic debris, and while current reports claim that it has dropped to third, it is not a significant change. Although some progress has been made, it still remains a challenging problem due to the country’s large population. This is one of the reasons why the GIDKP organization makes a point to push for systemic change as without changing the laws, it will be very difficult to manage the issue due to the sheer size of the country and its population.

That’s also why we work in collaboration with the Ministry of Environment and Forestry to be able to hit all regions in Indonesia, even in its remote areas.

As discussed earlier, the apparent increase in online shopping also becomes a major contributing factor to the issue. Although on the one side, it helped support local businesses in light of the covid 19 pandemic, reports emerged that in 2020 the generation of single-use plastic waste doubled in numbers because people couldn’t leave their homes and resorted to e-commerce and online delivery platforms to shop from.Recent events provide some positive news. Over 100 local governments have already passed laws banning single-use plastics in Indonesia alone.

Moreover, in some areas such as Bali and the Bogor Regency, the ban extends to the use of styrofoam and plastic straws. Even though it's only a third of the local governments in Indonesia for now, the ban is still a step forward for the country. Additionally, other than its enactment, improvements could also be made from the government’s side to ensure proper implementation of the ban in order to maximize results, because, with poor implementation, the ban would become redundant as there would still be some leaks in the system. As for the impact of the issue, adding to the factors that have been previously mentioned, the problem is quite severe. Closures of several TPAs (landfills) due to issues of overloading is one of the many proofs that the waste problem in Indonesia still presents as a big homework for the nation.

↘ Indonesia as the 2nd biggest marine plastic contributor in the world. ↘ Bye Bye Plastic Bags campaign in Bali.4. Has attempts by the government and the industry been made to tackle the issue?

There are a lot of fake solutions circulating which are offered in industries and even implemented by the government itself.

For example, Waste-to-Energy proposes the idea of using waste to generate electricity that in reality, doesn't solve the waste problem at all and actually exacerbates the issue; becoming an additional factor that worsens the waste problem in Indonesia.

These Waste-to-Energy power plants which were once considered a logical solution to our plastic problem actually have harmful side effects in the form of highly toxic ‘mud’ which has been tested by our sister organization called, the Nexus3 Foundation. Secondly, it has an output in the form of ash or smog which arises from burning plastic; these are very hot, are dark black in colour, and contain microplastics. Microplastics are another part of the problem that needs to be a topic of discussion because microplastics are indeed proof that the plastic problem is no longer just an environmental problem, but has become a health hazard as well. There have been many studies that discovered traces of microplastics in our digestive system and in our bloodstream, invading as far as the fetuses of pregnant women. Although clearly horrifying, the extent of its harm is still being researched. These side effects may take up to several years to surface; in contrary to smoking, where the side effects are much more apparent and immediate. Nevertheless, there have been many studies that show that microplastics can also affect the production channel, causing pain and so on, therefore this is also not something we can underestimate due to its binding effect and potential for cancer. To make matters worse, now there’s even talk not only on microplastics but nano plastics, which are even smaller, invisible, and can be found literally everywhere.

Last year, our friends at Greenpeace conducted research on various water bodies in Indonesia and all of them were found to be contaminated with microplastics. This confirms that we are already surrounded by microplastics everywhere. Apart from the environmental impact, like polluting our environment by making it smelly and dirty, not to mention the effects from the production process of making plastic which produces greenhouse gas emissions that contribute to the current climate crisis, there are we give health effects as well.

↘ Nexus3 Foundation. ↘ Green Peace Indonesia.To add on, there are a lot of big companies that promote recycling as a solution to this plastic crisis. Although seemingly harmless on the surface the situation is different behind closed doors.

Some time ago, our sister organization from the Zero Waste Indonesia Alliance held a trip to the city of Surabaya to visit a sachet recycling factory, which ironically turned out to be one of the top polluters in the area. This trip happened as the organisation was in the middle of a mission to tackle sachets which are notoriously very difficult to recycle due to their multi-layer components. A company had reached out to them and said that they have the means to do it. So the organization took a trip to their facility and was shocked to find how unsafe the facility was. Some of the organization members noted a very putrid, chemical smell they couldn't begin to describe as they were approaching the factory. Upon entering, they were surprised to find that workers in the facility did not use any form of safety equipment. Inhaling the air from the recycling process is extremely dangerous due to the presence of microplastics, not to mention the involvement of heat in the process which might lead to a lot of toxic chemical fumes to be exerted that are harmful to our health.

How are these workers so oblivious to the harmful effects involved in their work?

Before companies aim to educate their consumers on recycling, they should first talk about the safety of their recycling factory workers.There is an urgent need to thoroughly review the whole landscape of recycling in Indonesia. If a company is really advocating for recycling, to what extent can it guarantee the well-being of its workers who are doing the work? Regardless, this was just additional information which in my opinion is also quite important to highlight because recycling has become a trend recently, which of course is great, but from there we need to take a step back and ask ourselves if the system in place considers the safety of everyone involved— not only for consumers and the environment but also for the workers themselves. After all, possible tactics to tackle plastic pollution would only be considered a “solution” to the problem if it takes into account the well-being of all parties involved.

↘ add link to azwi5. Can you elaborate more on the dangers of single-use plastics?

The main aspect we problematize is the single-use nature of plastics. Plastic as a material is everywhere; they are in our clothes, gadgets, water bottles and food containers. But what is truly harmful is the single-use nature of plastic bags. The importance of reusing is something we always try to get across to our audience.

Furthermore, sachets as previously discussed are also considered single-use plastics. Now the problem is that some garbage banks actually do not take in sachets anymore due to their non-recyclable nature, opting to dump them in landfills instead. This is exactly why we problematize single-use plastic products that end up polluting the environment.

We often emphasize that the act of reusing is key.

If for example, a person opted to switch from plastic to biodegradable paper bags, it would still be redundant if these paper bags are only used once because then it is no different than single-use plastic bags in their quick conversion to waste. Some people would justify their use of paper bags because it is able to decompose naturally, and yes, although it is good for the environment, the solution to our waste problem is if we make reusing a habit. This issue is actually similar to the stainless straw dilemma. Recent research articles have highlighted how the production of stainless straws actually has bigger emissions than plastic straws. But indeed once again what is pressed is the single-use nature of these products. People often have the misconception that plastic bag alternatives are always expensive and that we have to buy them continuously.

When we talk about coming up with a solution to our waste problem, it doesn’t mean we have to buy new sustainable products. So even though these alternative options might have a higher emission during their production, if it means that we will be using the item constantly and not need to use disposables anymore, then we are indirectly suppressing the production numbers of single-use products, and in turn, the number of gas emissions during the process.

6.GIDKP has successfully become the initiator of the Pay for Plastics trial and this is an extraordinary achievement. Can you tell us a little about the activities and research that GIDKP has done to encourage people to reduce plastic consumption?

So our executive director Tiza Mafira initiated the petition in 2013. At that time, “Pay for Plastic” was just a mere movement. Various individuals and organizations were involved in this campaign, but Mrs Tiza was the lead initiator. Finally, a petition was made through the Change.Org platform.

Eventually, the Ministry of Environment and Forestry agreed to back up this initiative, which gathered over 60,000 signatures.

As far as I remember, with the petition getting the seal of approval from the Ministry of Environment and Forestry, the trial run for the “pay for plastic” law was implemented in 23 provinces designated by the Ministry of Environment and Forestry for 6 months. The trial run succeeded in reducing plastic use by 55% based on research released by the Ministry of Environment and Forestry. We saw very positive outcomes from this trial run which also lead to a snowball effect like in the city of Banjarmasin which was inspired by the success of the trial run and finally became the first city in Indonesia to ban plastic bagss.

So this is something quite exciting for us because we were able to observe the apparent willingness of regional governments to reduce plastic, with little push and guidance. It might be difficult for the Ministry of Environment and Forestry to assist each and every city, so for this reason, the GIDKP organization is always racking its brains to support the Ministry of Environment and Forestry.

Together in collaboration, we hope to jointly assist local governments to develop this regulation strategically and implementing it to ensure that single-use plastic reduction programs in their respective cities can run effectively and on target.

7.1 So you could say that the program was met with a lot of positive responses?

Yes, it was overwhelmingly positive.

7.2 Were there any difficulties you faced in the process?

What's really noticeable is that in 2019, the enactment of the PERGUB 142 law caused a lot of stir in the capital city DKI Jakarta, due to the people protesting that it affects business opportunities in the city. For a bit of background, the PERGUB 142 law is a ban on plastic in the province of DKI Jakarta, however, it was not the first as many local governments had also banned plastic, one of which is the province of Bali.

At that time, it was quite clear that there were those who were opposed which resulted in Tiza and her team being taken to court because someone had filed a lawsuit against the prohibition of the use of plastic in Bali.

Luckily in the end, the organization won the trial. So as presented, the situation can be quite intense as there are parties who are not happy and would make a fuss about the plastic ban for fear it will harm their business.

Apart from the province of Bali, this incident also occurred in the province of DKI Jakarta during yesterday's PERGUB 142. It is worth noting that the ban in Jakarta is more specific. While the bans in other cities only cover plastic bags, the ban in the capital also lists specific materials that are prohibited such as bioplastics or biodegradables as well.That is also one of the reasons why GIDKP has received a lot of attention because GIDKP has assisted in the process of making PERGUB 142.

You can check the Kopernik website to find out more about why bioplastics/biodegradables are banned because indeed again, the narrative pushes for single-use properties and the selling point of bioplastics is that they are sourced from organic materials such as cassava, but actually they still use plastic particles. For this reason, GIDKP and several other organizations under AZWI still disagree with bioplastic or biodegradable solutions.

8. Can plastic bags be completely banned? What about traditional markets that still need plastic to wrap meat and vegetables?

The traditional market is indeed quite challenging, therefore, GIDKP has started to clamp down on the plastic-free market program since 2019. Market management can encourage its traders to use less plastic, but cannot completely ban them, with the exception of some local governments such as Jakarta where traditional markets are also one of the legal subjects regulated for single-use plastic. That's why GIDKP is also part of the plastic-free market program, we strive to educate people that shopping at traditional markets can be done without using a plastic bag. For example, the plastic bag can be replaced with a tote bag or plastic containers you already have at home. The same applies to, say, when buying wet food ingredients such as meat, tofu and so on.

Therefore it is very possible to shop without plastic bags in traditional markets, but again, it's up to the will of the individual. Although many people say that it is difficult to shop without plastic bags, through educational videos and tips that we share online, we have proven that it is indeed very feasible. What is needed is consistency, not only from consumers but also from the traders, which we hope to carry out through this plastic-free market program. Through this program, we encourage traders by making a kind of protocol in which we invite traders to participate in educating their consumers because we are aware that the success of this program depends on the main actors in traditional markets, namely traders who interact with their consumers every day. We consider these traders to be "local champions" in traditional markets because they play a very important role in their interactions with consumers.

To answer the question of whether it is possible for traditional markets to operate independently of plastic bags, the answer is yes, however, it would take some time as it requires change in the society where people have made a habit out of using plastic. Habits, especially ones that occur everyday and involves many people, does not change overnight.

9. After all the attempts organizations like GIDKP and the government have made to try and tackle the problem of plastic pollution, what remains a main obstacle?

Apart from the plastic-free market program, we are also initiating a new movement called the Reuse Movement Jakarta. What we see to be a major problem is perception. When talking about environmentally-friendly solutions, people already have a prior perception that it is expensive and complicated. The existence of this misperception greatly affects individual behaviours, which in turn reduces the motivation to act. This is quite challenging because again, perceptions and habits are things that are difficult to change. If we are consistent in disseminating information on eco-friendly solutions, it might just motivate people to do it. But again, yes, in my opinion, the main obstacle is the factor of misperception itself. To me, I do not agree with the claim that sustainable solutions don't exist because the solution already exists right in front of our eyes and in our own homes — in the form of canvas bags and tumblers.

The second problem is the spread of misinformation that led to these misperceptions. As I have discussed before, for example, during the ban on plastics in Jakarta, there was an apparent rejection from several industries, especially the plastics industry, which greatly affects how they decorate the media, in the sense that it would later lead to the emergence of hoaxes, etc., especially during the PERGUB yesterday which coincided with Covid 19. So in my opinion, that is also one of the inhibiting factors because individuals are quick to absorb the news; especially the highlights. For this reason, organizations are always keen to justify wrong narratives. And lastly, further elaborating on my previous point, is the number of people promoting fake solutions. Especially when talking about Waste to Energy, which caused a lot of confusion amongst the public and that is proof that the narrative manipulation by the industry has succeeded in brainwashing people with misinformation.

To summarize, misperceptions and the dissemination of false information are major bottlenecks that are difficult to change once it sinks in and we are always struggling to find ways to help people differentiate between true and false facts. The documentaries Plastic Island and Story of Plastic are one of our methods to refute this. Katiza was involved in both documentaries which in fact became tools for us to refute wrong narratives circulating in the media.

10. From your experience, what is the most effective way to make people aware of the long-term harms of plastic pollution?

Getting the right information to people is important. That’s why education and campaigns are important factors because even though laws and restrictions play a crucial part when talking to the community, a different approach is more ideal. We could take the recent implementation of the obligation to wear masks during the pandemic. We were able to observe and learn from that experience how people would react. The sad realization is that even with things being a health hazard, it is still rather difficult to get people to comply, more so the problem of plastic pollution whose impact on health is not very visible.

10. Lastly, what are your hopes moving forward?

Firstly is that I hope each person at least makes an effort to reduce plastic use. What I often highlight is that we don't need to completely stop using plastic which can be considered quite overwhelming. Instead, I always put more emphasis on an individual devising a personal plan catered to their habits to slowly cut down on using plastic in their routine. Hopefully once successful, these individuals can then turn to educate the people around them, which brings me to my next point.

Secondly, I hope that more people would spread environmental awareness to the people around them. It is difficult if we are alone in this battle, yet with the power of a few, a huge impact can be made, even if individually, the cutbacks on plastic are minute.

For the aspirations of the GIDKP organization itself, the third is to devise a method for the regional or central government to be able to work closely with all actors in their respective regions because again, what we want to highlight is systemic changes.

For the aspirations of the GIDKP organization itself, the third is to devise a method for the regional or central government to be able to work closely with all actors in their respective regions because again, what we want to highlight is systemic changes. If for example talking about systemic change, there is a need for all parties in the ecosystem to get involved together in a sustainable ecosystem. Recently, GIDKP created the Reuse Infrastructure Grid, where we created an ecosystem to enable all parties in the city of Jakarta to contribute to this re-use ecosystem so that, aligning with a saying by the UN, no one gets left behind. Synergy and commitment are the keywords in order to succeed together in creating an environmentally friendly ecosystem.

Fourth would be for no more public misperceptions of the false narratives and solutions around plastic pollution as mentioned earlier because, in my opinion, the media has great power over individuals because their knowledge of certain things would ultimately dictate their behaviour.

And the fifth and final hope, in light of the upcoming 2024 election, is for our new leader to take responsibility to support the right solution for all Indonesians and our environment.